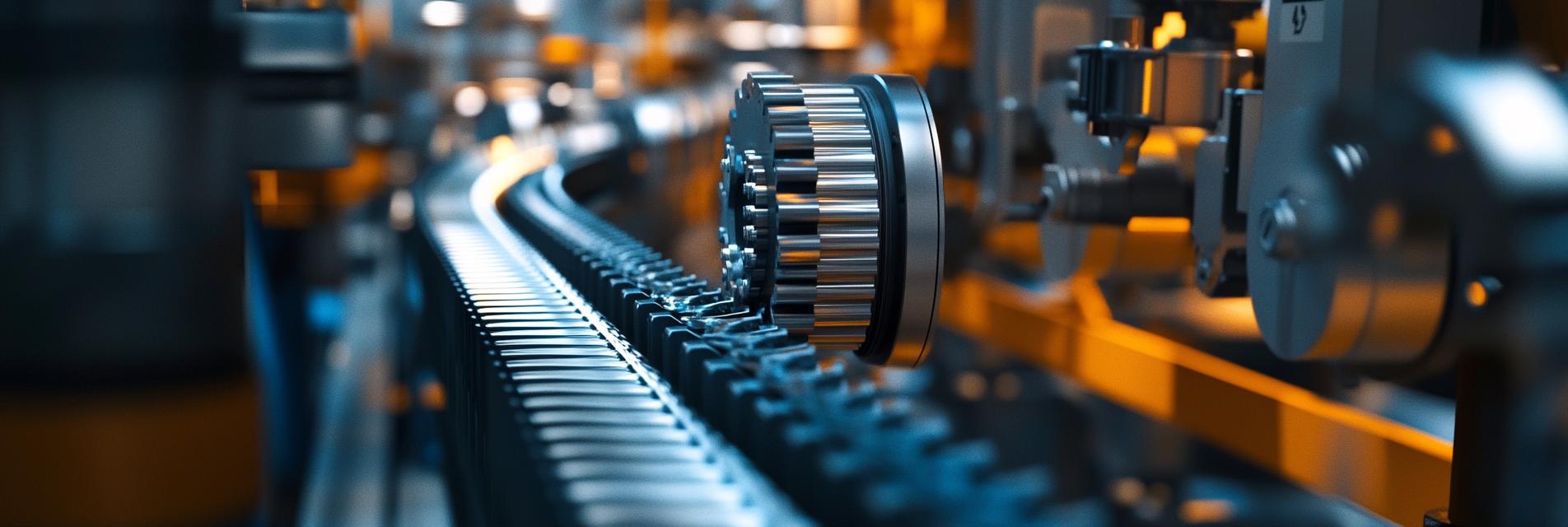

In the world of industrial operations, the choice of conveying equipment is pivotal for efficient material handling. Selecting the appropriate conveying equipment ensures not only smooth transitions in the workflow but also enhances overall productivity. This guide delves into the key technical parameters to consider when making your selection.

When evaluating conveying equipment, there are several fundamental technical parameters that can significantly influence your decision:

The load capacity of a conveyor is one of the most critical parameters. It defines how much weight the equipment can handle at any given time. This factor is vital for ensuring the safety and longevity of the equipment.

Conveyor speed impacts the efficiency of your operation. Assess the required speed for your production line to find the optimal equipment that meets your operational needs without compromising quality.

Not all conveying equipment is suitable for every type of material. Understanding the material's properties such as size, weight, and fragility can guide you in selecting the right equipment that minimizes damage and enhances operational efficiency.

Choosing the right conveying equipment involves a systematic approach. Here’s a quick selection guide:

Choosing the right conveying equipment is crucial for maximizing efficiency in material handling processes. By understanding the key technical parameters and following the selection guide, businesses can ensure optimal performance and productivity. Stay informed and equipped by continuously exploring advancements within the conveying equipment industry.